X-ray Nanotomography: in-situ measurements

Last modified by flenners on 2022/11/17 13:24

Currently available:

Nanoindenter

Micropillars (eg. milled using FIB or any etching techniques) – Compression of micropillars for stress-strain curves and determining yield strength, loading modulus, fracture strength (in case of brittle materials), compressive strength, etc.

- Microcantilevers (eg. milled using FIB or any etching techniques) – Bend tests on microcantilevers for determining fracture toughness, critical energy release rate, study interfacial adhesion of thin films and multilayers, etc.

- Time dependent properties (in both indentation and micropillar compression): Creep, strain rate sensitivity and stress relaxation. Transient creep exponents, relaxation time constants, activation volumes and strain rate sensitivity exponents can be determined.

- Low cycle fatigue tests in indentation, micropillar compression and microcantilever bending

- Scratch tests – nanoscale wear tests

- Sinus mode indents: For studying viscoelastic properties of polymers, studying change in mechanical properties of multilayers and functionally graded materials as a function of indentation depths

- Repeated impact tests – delamination of delamination behaviour of films and coatings

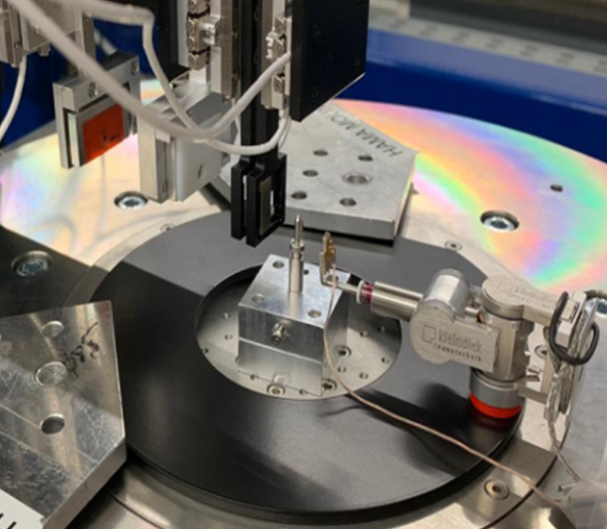

Micropamipulator

Different plug-in tools available

-Force measurement system

-Microgripper

-Micropipette

-Micro soldering unit